Sheet Metal: The “Behind-the-Scenes” MVP of Your Business

In business, a lot of success depends on the things customers never see. They notice fast service, clean facilities, and products that work as promised. But behind the scenes? The real heroes are often things like ductwork, equipment enclosures, brackets, transitions, fittings, and structural supports—all made possible through sheet metal fabrication.

That’s why choosing a professional team for metal fabrication in Columbus Ohio matters more than many business owners realize. Sheet metal isn’t just metal—it’s function, airflow, safety, durability, and performance wrapped into one.

At The Sheet Metal Shop, we work with Central Ohio business owners and contractors who need precise, high-quality results. Whether you’re managing a facility, upgrading a system, or building something new from scratch, professional sheet metal services provide reliability you can build on (literally).

Let’s break down what makes sheet metal fabrication so important—and why the right contractor can make your life much easier.

What Sheet Metal Fabrication Really Means (Beyond “Bending Metal”)

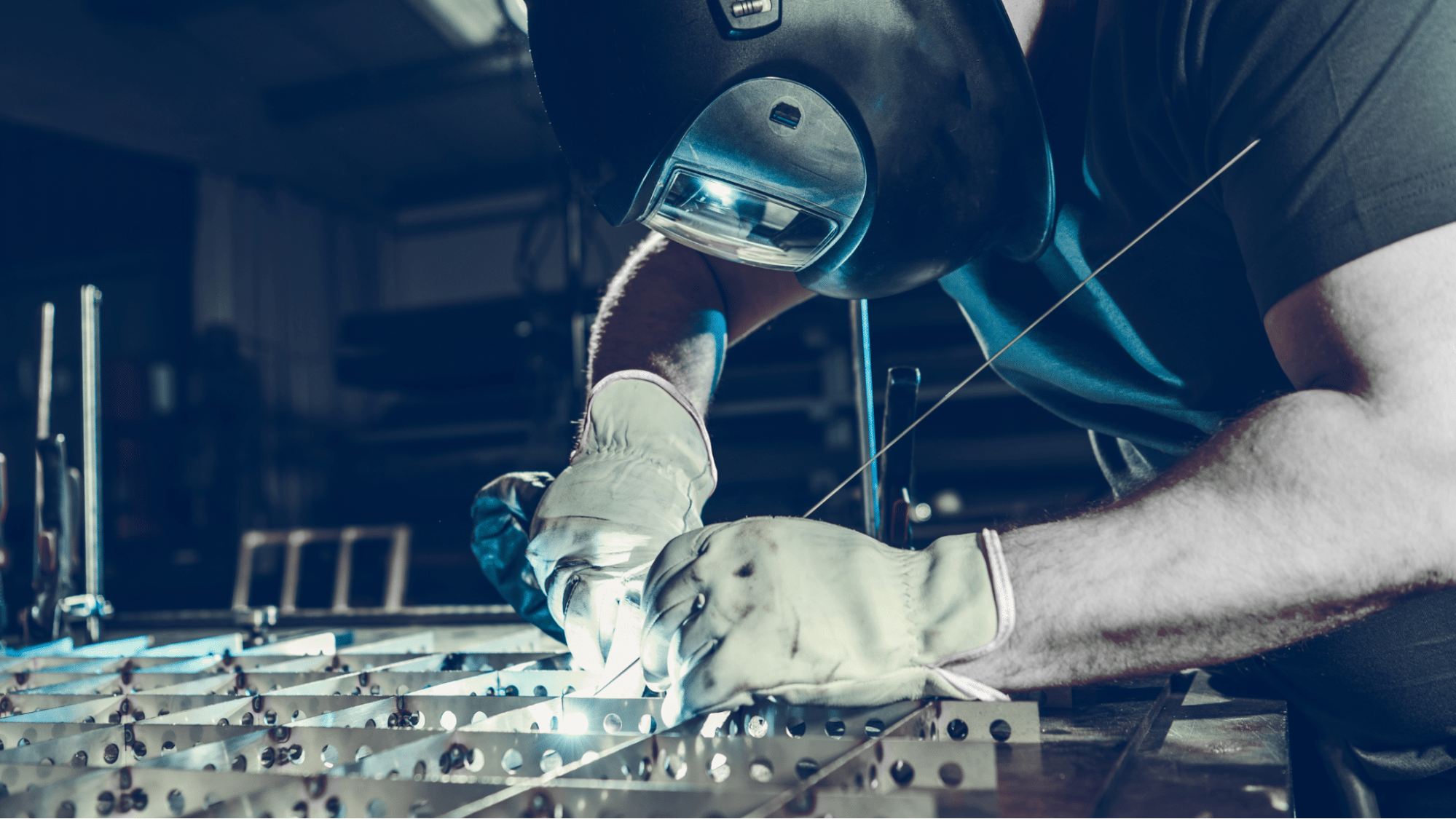

It’s easy to assume sheet metal fabrication is simply cutting metal and shaping it. In reality, it’s a highly specialized process that combines engineering, craftsmanship, and precision.

Sheet metal fabrication can include:

- Cutting and shearing

- Forming and bending

- Rolling and shaping

- Welding and assembly

- Finishing and reinforcement

Each step requires the right equipment and experienced hands. A minor measurement error in fabrication can lead to major headaches during installation.

And if you’ve ever tried forcing a piece to fit when it was fabricated incorrectly, you already know: metal does not respond well to “close enough.”

Why Metal Fabrication Columbus Ohio Is a Smart Local Advantage

Columbus is a fast-growing region with busy commercial development, industrial operations, warehouses, medical facilities, and manufacturing plants. That means one thing: the demand for reliable, high-quality metal fabrication in Columbus Ohio is constant.

Working with a local fabricator offers key benefits such as:

Faster Turnaround

Local teams can typically produce and deliver projects more efficiently than out-of-town suppliers—especially for custom work.

Better Communication

Need adjustments? A revised design? A quick consultation? Local partnerships make communication faster and easier.

Long-Term Support

When you hire a local shop, you’re building a relationship, not just making a purchase.

Want to learn more about our company and approach? Visit us online at The Sheet Metal Shop.

Sheet Metal Quality Impacts More Than Appearance

Sheet metal might look like a background detail, but it affects major systems that keep your business running smoothly.

Poor-quality sheet metal work can cause:

- Airflow leaks and HVAC inefficiency

- Excess vibration or noise

- Structural weakness

- Faster corrosion or damage

- Frequent repairs and replacements

In many commercial settings, sheet metal fabrication plays a direct role in:

- Indoor air quality

- Temperature control

- Safety compliance

- Operational efficiency

It’s not just about having sheet metal—it’s about having the right sheet metal.

The True Cost of Cheap Fabrication (Spoiler: It’s Not Cheap)

When budgets are tight, it’s tempting to choose the lowest bid. But in sheet metal fabrication, the cheapest option can become the most expensive one—fast.

Here’s what low-quality work often leads to:

- Rework and wasted labor hours

- Project delays and downtime

- Increased energy consumption

- Premature system failures

- Frustrated contractors and facility managers

A common real-world example: poorly sealed or poorly fitted ductwork that leaks conditioned air. That doesn’t just lower comfort—it increases energy bills month after month.

Professional fabrication delivers precision and consistency, saving money over the lifespan of the system.

Custom Sheet Metal Fabrication vs. Off-the-Shelf Components

Standard components may work for basic applications—but businesses rarely operate in “basic” environments. Custom fabrication often becomes necessary due to:

- Unique building layouts

- Specialized equipment

- Space limitations

- Retrofitting older facilities

- High-performance airflow needs

Custom sheet metal fabrication offers:

- Exact-fit parts that reduce installation time

- Better system performance

- Cleaner, more durable assemblies

- Solutions designed around real-world usage

If your system or project needs to work efficiently on day one—and stay efficient for years—custom fabrication is often the best path forward.

Industries That Rely on Professional Sheet Metal Work

Many business owners don’t realize how many industries depend on sheet metal. In Central Ohio, sheet metal fabrication is commonly used in:

- Commercial HVAC systems

- Manufacturing facilities

- Warehouses and logistics operations

- Food processing plants

- Retail centers and office buildings

- Medical and lab environments

These industries depend on durability, precision, and code compliance—especially in systems tied to air quality, temperature control, and equipment safety.

How Professional Sheet Metal Contractors Ensure Precision and Durability

The difference between average fabrication and excellent fabrication comes down to expertise, tools, and attention to detail.

Professional contractors focus on:

- Accurate measurements and layout

- Proper material selection

- Clean welds and strong joints

- Reinforced structural integrity

- Smooth fit-up for easier installation

At The Sheet Metal Shop, quality control isn’t a checkbox—it’s the foundation of every project we deliver.

Want to see what we do? Explore our services here: https://sheetmetalshopcolumbus.com/services/.

Materials Matter: Choosing the Right Sheet Metal for the Job

Different applications require different materials. Professional fabricators help business owners select the best option based on durability, environment, and performance goals.

Common sheet metal materials include:

- Galvanized steel (great for ductwork and corrosion resistance)

- Stainless steel (ideal for harsh or sanitary environments)

- Aluminum (lightweight and corrosion resistant)

- Carbon steel (strong, versatile, and cost-effective)

Material selection impacts everything from lifespan to maintenance requirements—and choosing wrong can lead to premature failure.

Why Compliance and Safety Standards Can’t Be Overlooked

In many commercial applications, sheet metal is part of systems governed by building codes and industry standards. Poor fabrication can create compliance issues and safety risks.

Professional fabrication helps ensure:

- Proper airflow performance

- Secure fastening and support

- Safe equipment enclosures

- Reliable system integration

This matters for both inspections and long-term liability protection. In other words: professional sheet metal work is the safer business decision.

Who We Are: The Sheet Metal Shop in Columbus, Ohio

At The Sheet Metal Shop, we’re proud to support Central Ohio businesses with expert craftsmanship and responsive service. We don’t believe in rushed jobs, sloppy seams, or “good enough.”

We believe in:

- Clean work

- Strong builds

- Precise fabrication

- Professional communication

If you’d like to learn more about our background and approach, check out our About Us page.

What Customers Say About The Sheet Metal Shop

When choosing a fabrication partner, trust matters. Businesses across Columbus and surrounding areas rely on our quality work and professional service.

You can check out our reviews and see what customers say on our Google Business Profile right here:

The Sheet Metal Shop Google Listing.

When Should You Call a Sheet Metal Fabrication Professional?

If your business needs:

- Custom ductwork

- Equipment modifications

- System upgrades

- Reliable metal components

- Improved efficiency or durability

…it’s time to call a professional fabricator. Early planning reduces surprises and helps projects run smoother from start to finish.

The Bottom Line: Sheet Metal Work Is Worth Doing Right

Professional sheet metal fabrication is about more than metal—it’s about performance, reliability, safety, and long-term value. For businesses seeking dependable metal fabrication in Columbus Ohio, choosing experienced contractors ensures every piece fits, functions, and lasts.

If your business depends on HVAC efficiency, durable equipment, or structural reliability, quality sheet metal work is one of the smartest investments you can make.

Ready to Start Your Sheet Metal Project?

Reach out to us!

Be sure to reach out to us if you have any questions—our team is here to help.

📞 Call 614-989-6835

💻 Contact us online: https://sheetmetalshopcolumbus.com/contact-us/

To learn more about our services, visit The Sheet Metal Shop—where Central Ohio businesses get sheet metal work done right the first time.

Frequently Asked Questions About Sheet Metal Fabrication in Columbus, Ohio

What is sheet metal fabrication and why is it important?

Sheet metal fabrication is the process of cutting, bending, forming, welding, and assembling sheet metal into custom parts or systems. It’s important because professionally fabricated components fit properly, perform efficiently, and last longer—especially in commercial and industrial environments.

What types of businesses benefit from metal fabrication in Columbus Ohio?

Many industries rely on metal fabrication Columbus Ohio, including:

- Commercial HVAC contractors

- Manufacturing and industrial facilities

- Warehouses and distribution centers

- Food production and processing plants

- Healthcare and laboratory settings

- Retail and office buildings

Any business that depends on durable equipment, air movement, or structural support can benefit from quality fabrication.

What materials are commonly used in sheet metal fabrication?

Professional fabricators work with several types of metal depending on the project needs, including:

- Galvanized steel (excellent for ductwork and corrosion resistance)

- Stainless steel (ideal for sanitary or high-moisture environments)

- Aluminum (lightweight and corrosion resistant)

- Carbon steel (strong and cost-effective for many applications)

Choosing the correct material helps maximize lifespan and performance.

Why should I hire a professional sheet metal contractor instead of ordering prefab parts?

Prefab parts can be convenient, but they don’t always fit correctly or perform as efficiently in real-world systems. Hiring professionals for sheet metal fabrication helps ensure:

- Precise measurements and fit

- Better system performance

- Reduced installation time

- Increased durability and reliability

Custom fabrication often prevents costly modifications during installation.

How does sheet metal quality affect HVAC efficiency?

In HVAC systems, poorly fabricated ductwork can lead to air leaks, restricted airflow, and pressure loss. Quality sheet metal fabrication helps maintain:

- Proper airflow balance

- System efficiency

- Energy savings

- Better indoor comfort and air quality

Even small gaps or poor alignment can create long-term performance issues.

How long does a typical sheet metal fabrication project take?

Project timelines vary based on complexity, materials, and scope. Smaller custom parts may be completed quickly, while large-scale system fabrication may take longer. A professional shop can provide accurate turnaround expectations after reviewing project details.

Can sheet metal fabrication be customized for unique equipment or building layouts?

Yes. Custom sheet metal fabrication is ideal for projects involving:

- Tight installation spaces

- Retrofitting older systems

- Specialty equipment enclosures

- Non-standard ductwork designs

- Structural supports or custom components

Custom work ensures everything fits and functions as intended.

Is professional metal fabrication more expensive than low-cost options?

Professional fabrication may cost more upfront, but it usually saves money long-term by reducing:

- Rework and installation delays

- Ongoing maintenance needs

- System inefficiency

- Premature replacement costs

In most cases, quality work pays for itself through performance and durability.

Do sheet metal contractors help with design and planning?

Yes. Professional contractors often work with business owners, facility managers, and other trades to ensure fabricated parts meet the project’s specifications and performance requirements before fabrication begins.

How can I contact The Sheet Metal Shop for fabrication services?

Getting started is easy:

📞 Call 614-989-6835

💻 Contact us online: https://sheetmetalshopcolumbus.com/contact-us/

🌐 Learn more about our services: https://sheetmetalshopcolumbus.com/services/