Key Takeaways

- Opt for a local Columbus metal fabrication partner to reduce lead times, enhance coordination and tap into local talent and cutting-edge machinery. We prioritize face-to-face planning and local site visits to reduce rework and maintain milestone schedules.

- Enjoy faster turnaround by slashing transit time and making it easy to iterate on urgent repairs, prototypes, and production parts. Sync fabrication slots to your build schedule to hit hard deadlines consistently.

- Get better project results by communicating directly with your engineers to collaborate on designs, tolerances, and finishes. Leverage in-person review and real-time updates for specification validation before cutting, forming, and welding start.

- Strengthen your supply chain by tapping into metals and components from reliable Ohio suppliers for steady accessibility and reduced shipping emissions. Utilize JIT deliveries to manage inventory and minimize carrying costs.

- Back Columbus – with local jobs, training, and manufacturing capacity. Establish long-term relationships that build your vendor network and your brand.

- Require excellence and sustainability via certified processing, material traceability, and recycling. Request certified inspection, AWS and ISO certification, and green finishing options to fulfill performance and sustainability objectives.

Metal fabrication in Columbus, Ohio refers to the local industry that cuts, forms, and joins metal into parts and systems for buildings, HVAC, manufacturing, and custom projects. Shops here process carbon steel, stainless steel, and aluminum with CNC lasers, press brakes, MIG and TIG welders, and powder coat lines.

Lead times frequently are 1 to 3 weeks on typical work. For facility upgrades or duct handiwork, specifications, tolerances, and finish class count too. The next few sections map vendors, pricing, and when pros should intervene.

Why Choose Local Columbus Fabrication?

Choosing a Columbus-area metal shop for your custom machining and metal fabrication needs results in speedier lead times, more precise coordination, and immediate connection to expert crews who understand local codes and jobsite realities, benefiting owners and facility managers.

- Faster project completion: Proximity cuts wait times, eases logistics, and speeds QA sign-offs.

- Direct access: meet certified fabricators (often ISO and engineers in person.

- Smoother coordination: Local site visits reduce rework and schedule risk.

- Community impact: Spending stays in Columbus, building trusted, long-term partners.

- Cost control: lower transport, shorter queues, and fewer change order cycles.

- Broad capability includes design, engineering, material selection, cutting, forming, welding, and finishing.

Faster Turnaround

Shorter lead times lead to same day kickoffs, fast design reviews, and rapid prototyping. Local teams can move machines to priority runs, which comes in handy when a structural bracket, custom plenum, or guardrail needs to ship in 48 hours.

Shipping delays shorten because parts travel a few miles, not across borders. You reduce freight risk, packaging expense, and harm to thin-gauge panels or precision jigs.

Emergency repairs get priority. A cracked weld on a boiler skid or a misfit duct elbow can be cut, formed, and reworked in a workday, not a week.

Tight deadlines stick with local scheduling. If a GC shifts a concrete pour, a Columbus shop can resequence laser cutting and press brake slots the very same morning.

Clear Communication

|

Strategy |

Practical Use |

Impact on Outcome |

|

Daily stand-ups |

10-minute calls with PM, welder lead, QC |

Faster issue resolution |

|

Markup reviews |

Live CAD/print markups in shop |

Fewer design errors |

|

On-site checks |

Fit-up checks before final weld |

Less rework, better fit |

|

Shared trackers |

Cloud logs for milestones and NCRs |

Transparency, predictable dates |

On-site consults keep spec drift out. A 2 mm tolerance on a stainless enclosure or just the right alloy pick for corrosion duty gets sealed in before metal is cut.

Allows design changes to stay in check. Rev tags, updated DXF files and fixture tweaks are reviewed face-to-face so the finished part matches the drawing, not a guess.

Trust builds when updates are consistent, transparent, and recorded. That de-risks complicated builds for construction, manufacturing, automotive, or aerospace projects.

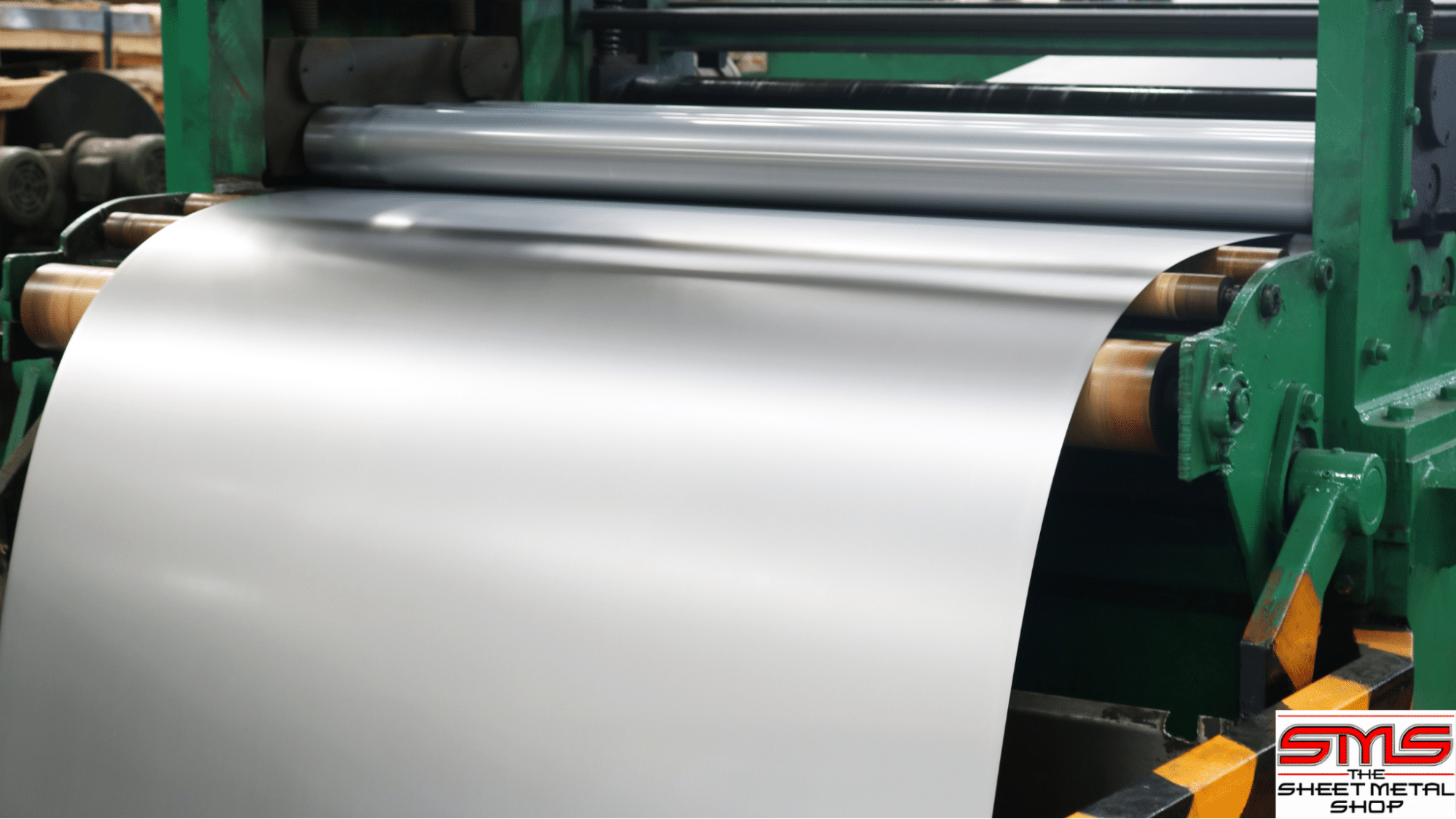

Local Sourcing

Ohio suppliers carry standard gauges and alloys, which is a real help when you need some 3 mm aluminum 5052, A36 plate, or 304 stainless and can’t wait weeks.

Transport is short, thus costs and emissions drop. This is important for high-volume runs and large assemblies.

We keep the material on hand during supply-chain swings. Local mills and distributors can interchange equivalents with certified certifications.

Vendor ties programs stable. Active purchases lock in priority of coil, plate, and tube.

Community Support

- Builds local jobs and training pipelines for skilled trades.

- Forges permanent connections with shops that understand your expectations.

- Lifts regional manufacturing and service networks that support uptime.

- Signals community care, which can help brand and hiring.

Our Columbus Metal Fabrication Services

Made for pressing deadlines and tricky blueprints, our premier metal fabrication team services design, build, and delivery for worldwide standards with transparent documentation and traceability from beginning to end.

- Cutting, forming, welding, machining, and finishing

- Custom builds for commercial, industrial, and construction projects

- Metals include carbon steel, stainless steel, aluminum, copper, and select exotic alloys.

- End-to-end management: CAD/CAM, prototyping, QA, logistics

- Capacity for large stock: up to 7.3 m length and 50 mm thickness

- Fleet support for installs: trucks with heavy-duty cranes

- One-off pieces and repeat runs supported

1. Precision Cutting

Laser, waterjet and HD plasma take on complex geometry and mixed materials with consistent precision. Tight tolerances apply across parts, even where heat input has to be carefully managed to safeguard edge quality or coatings.

From thin gauge to plate, with clean edges for downstream forming or weld prep. Normal jobs are brackets, custom hopper panels, tank head blanks and industrial platform gussets.

For prototypes and mass runs, nest plans minimize waste and accelerate turn times.

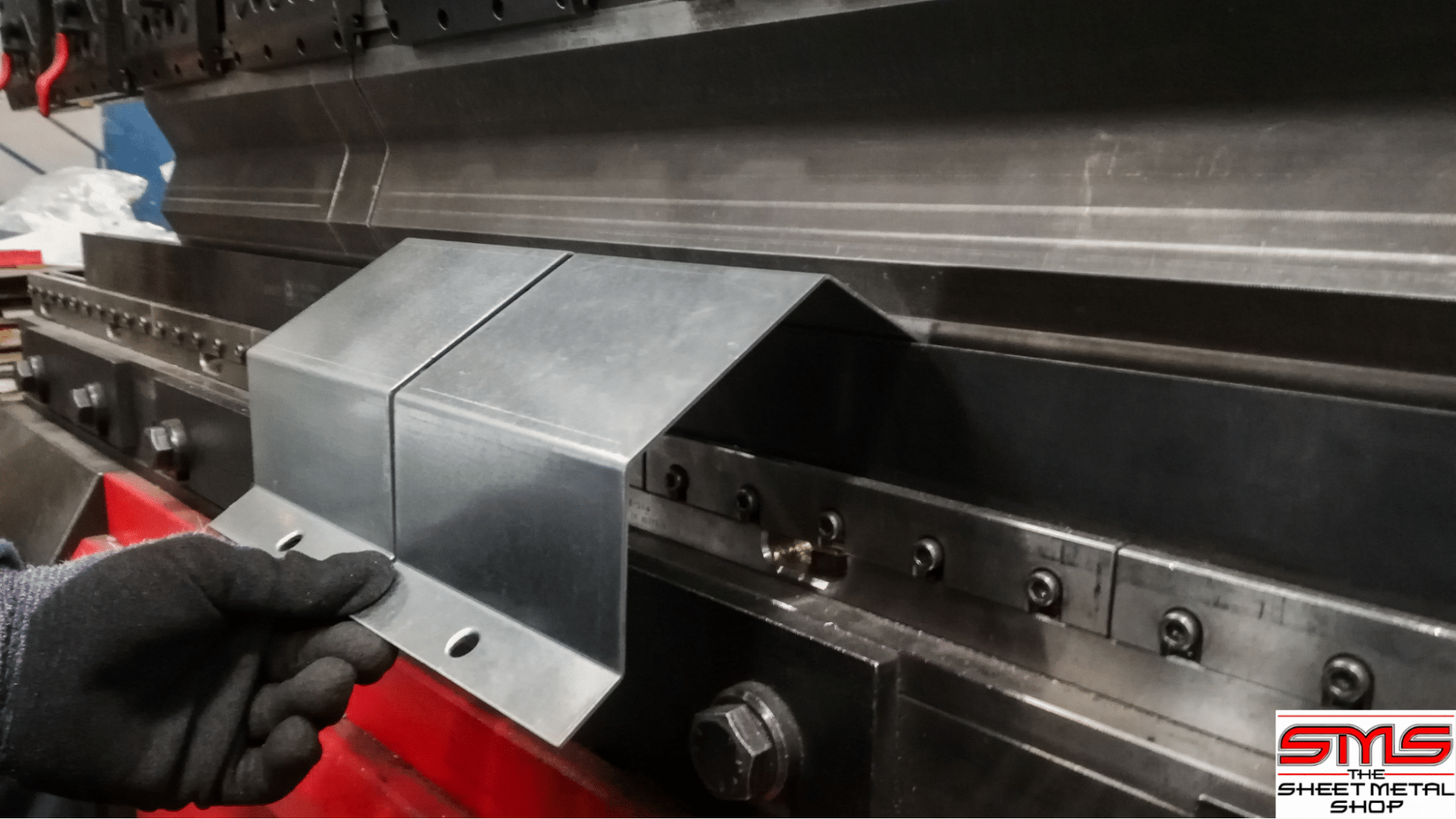

2. Custom Forming

We bend, roll, and form to spec utilizing press brakes with programmable backgauges, plate rolls, and section rolls. Repeatable angles, radii, and flatness are maintained through small batches and long runs.

Typical products are ductwork, enclosures, frames, guards, handrails and structural components for industrial, agricultural and commercial applications.

We embrace unique shapes and large formats. Segmented rolling and multi-hit forming enable us to fit tight spaces or match legacy components.

3. Expert Welding

MIG, TIG, stick, and robotic cells provide strong joints with controlled distortion and a clean appearance. We fusion weld carbon steel, stainless steel, aluminum, and dissimilars using appropriate filler and process.

Mobile repairs and on-site fabrication where downtime matters are provided by field crews. Weld integrity is verified with visual inspection, fillet gauges and, as necessary, dye penetrant or third party tests.

Sanitary, structural or painted service is available on finished results.

4. CNC Machining

CNC mills and lathes craft parts to precise tolerances, merging CAD files and transparent GD&T. Milling, turning, boring, and spline cutting of shafts, frames, and complex assemblies.

From prototype fit-ups to production parts and late-stage rework, we’ve got you covered. Machined features mate with weldments and formed parts so assemblies go in without shims!

5. Durable Finishing

Powder coat, paint, passivation and polishing build life and resist corrosion. Surface prep consists of blasting and chemical cleaning so coatings adhere and endure in tough environments.

Finishes achieve industry standards and align with color or gloss targets. We ship ready to install platforms with coated grating, tanks with food-grade interiors, or panels labeled for line-side assembly.

These are designed to withstand real wear and time.

Navigating Ohio’s Industrial Demands

Columbus occupies the hub of a dense supply network, with I-71 and other corridors connecting shops to automakers, builders, and aerospace tiers throughout the Midwest. Demand is broad: structural frames for construction sites, precision brackets for OEMs, enclosures for data centers, and custom ductwork that must align with HVAC codes. To meet these metal fabrication needs, companies rely on specialized welding services and custom machining processes.

Meeting that mix requires smart planning, precise scheduling, and the right machines on the floor — CNC mills, laser cutters, press brakes, and robotic welders — so small lots and large assemblies can run side by side without bottlenecks. Shops require a capable bench.

Ohio has roughly 4,883 machinists on the payroll, but there are still gaps for machinists, assemblers, and cutting and press machine operators, so training and cross-skilling count. The stakes are real: primary and fabricated metals add roughly $9.3 billion to state GDP.

Local Regulations

About: Steeling Ohio’s Industry Requirements Fabricators factor in load ratings, corrosion class, and fire-resistance requirements for commercial and industrial work. That impacts grade selection, finishes, and joint configuration.

Everything had to go through local inspection. We’re talking welder certifications, procedure qualification records, material test reports, and surface finish specs linked to drawings, not to mention traceable heat numbers. They seek compliance as constructed, not just as planned.

Teams track updates that impact structural steel, guardrails, seismic bracing, and electrical grounding for enclosures. When standards shift, process sheets and traveler packets shift with them.

Customers require concise documentation. Submittals, cut sheets, finish data and installation notes accompany permitting and field checks. Well documentation cuts days off schedules.

Supply Chain

|

Aspect |

Local Sourcing (Ohio/Region) |

Global Sourcing |

|

Lead time |

Short; days to weeks |

Longer; weeks to months |

|

Risk |

Lower; fewer transit variables |

Higher; shipping and customs delays |

|

Cost stability |

Moderate; less freight volatility |

Variable; tariffs and ocean rates |

|

JIT support |

Strong; quick replenishment |

Weak; buffer stock required |

|

Traceability |

High; easier mill cert access |

Mixed; longer chains |

|

Flexibility |

High for design changes |

Lower; frozen specs early |

Working closely with local mills and processors enables just-in-time runs, consistent coil and plate flow, and faster changeovers. It cushions it from shocks across the world and keeps initiatives moving forward.

Sustainability

- Utilize recycled feedstock, low-waste nesting, and high-yield blanks to reduce scrap at the source.

- Switch to energy-efficient lasers, inverter welders, and heat recovery on compressors to trim kWh use.

- Recycle offcut and chips. Segregate alloys to maintain material value and traceability.

- Opt for low-VOC finishes and powder coat lines that utilize closed-loop reclaim systems.

- Design for disassembly with bolted joints where possible to facilitate future reuse.

- We source our metals from ethically responsible mills that provide a verifiable chain of custody and EPDs.

- Meet Ohio’s industrial needs by providing verifiable recycled content and finish data for green building standards.

- Educate teams to minimize rework. This decreases energy, consumables, and lead time.

The Technology We Use

In Columbus, OH, we integrate custom machining and specialized welding services to ensure precision, efficiency, and consistent craftsmanship in metal manufacturing for both residential and commercial projects.

Employ advanced fabrication technologies, including fiber lasers, CNC machines, and robotic welding systems.

Fiber laser cutting achieves tight profiles on carbon steel, stainless steel, and aluminum with narrow kerf and low heat input that minimizes edge cleanup. Laser cutting is our default for intricate HVAC brackets, pump plates, and thin-gauge guards.

Advanced plasma takes over for thicker plates where clean, quick cuts matter. Robotic welding cells maintain torch angles and travel speed with a consistency that hand welding can’t replicate on long runs. This is useful for duct frames or structural skids.

Our three-axis CNC machines span milling, turning, boring, and spline cutting. This allows us to transition from flat parts to precision blocks and shafts without hopping between vendors. Heavy-duty, truck-mounted cranes relocate long beams and 24-foot sheets with less downtime and safer handling.

Invest in modern equipment for increased efficiency, precision, and production capacity.

Large capacity rollers plate up to 1.5 inches thick with uniform radius, which eliminates stress points and maintains roundness within spec for tanks and sleeves. On bends and forming, precision presses use 60 to 750 tons of clamping force.

With proper tooling, we maintain tolerances of plus or minus 1.6 mm (plus or minus 1/16″) on repeated bends. For plate up to 50.8 mm and components up to 7.3 m long, we combine plasma or laser with fixtured welding to keep it straight and with square corners.

On the floor, integrated material carts, forklifts and overhead cranes reduce changeovers and accelerate cycle time on mixed part orders.

Utilize CAD/CAM software for accurate design, simulation, and prototyping.

CAD models power flat patterns, bend allowances, and weldment layouts, slashing trial and error and scrap. CAM posts toolpaths for fiber laser, plasma, and CNC mills, with nesting to get more parts per sheet.

Simulation checks bend collisions, weld distortion risk, and tool reach before we cut metal. For HVAC housings or boiler plates, we create digital assemblies, then 3D printed mockups as necessary, so mounting points align on the initial fit.

From concept to completion, all under one roof: design, cutting, forming, machining, welding, inspection, less hand-offs, less lead time.

Continuously upgrade technology to stay ahead in the competitive metal fabrication industry.

We check machine uptime and cut speed and edge quality. Then we introduce newer laser sources, more intelligent CNC controls and offline weld programming.

Operator training follows the upgrades, so increases in speed don’t come at the expense of accuracy or safety.

Our Commitment to Quality

Quality in metal fabrication means parts fit, welds hold and finishes last. It means transparent estimates, secure job sites and no unexpected costs. For homeowners and property managers in Columbus, Ohio and beyond, that means less downtime, frictionless installs and increased longevity.

We construct to that quality with processes that are straightforward, rigorous and tested.

Adhere to strict quality control procedures throughout the metal fabrication process.

Control begins with inputs. We check mill certs on steel and alloys, validate heat lots and track traceability from plate to part. Drawings to contract review, weld symbols, tolerances and surface finishes are reviewed line by line.

We measure kerf, edge hardness and heat-affected zones during cutting, whether laser or plasma. Forming has bend allowance checks and radius gauges, so ducts, frames and housings fit on site without shims.

Welding is done per weld procedures with preheat logs on thicker sections and interpass temperature checks to avoid brittleness. For finishing, we measure coating thickness in microns and sandblast to profile when corrosion resistance is critical.

Every step has hold points, and no step proceeds without sign-off. That’s how we maintain consistency on return jobs, such as fan housings or boiler panels.

Maintain certifications such as AWS and ISO to ensure top-quality workmanship.

Certification is the minimum standard, not the maximum limit. Our welders are AWS D1.1 and process-specific qualified, such as stainless under D1.6, tested by third-party CWI inspectors.

Our system is ISO 9001 aligned, so document control, corrective action, and calibration are built in, not patched on. For clients in regulated work, this keeps us in line with codes and helps avoid rework, delays, or fines.

It provides a shared language for international teams that require trustworthy documentation.

Conduct thorough inspections and testing to guarantee product reliability and safety.

We combine visual inspections with dimensional and functional testing data. We conduct dimensional inspection using calibrated tools and when necessary, coordinate measurement for close fits, such as pump bases within ±0.2 mm.

Welds receive dye-penetrant or magnetic particle testing for surface flaws. Critical seams may receive ultrasonic scans. Pressure parts, hydronic tanks, for example, undergo hydrostatic tests with hold times and pressure decay logs.

Moving assemblies receive balance checks to reduce vibration that could destroy bearings or break frames. When paint or powder is specified for coastal or chemical environments, we test adhesion and salt spray to specification.

We share our findings with clients and own issues and fix them fast.

Deliver consistent, high-quality results that meet or exceed client expectations.

Consistency is the end zone. We log nonconformities, do root cause analysis, and shift the process so the same miss doesn’t come back.

Little things, such as cleanly cut access doors, square flanges, parts labeled in metric, and transparent packing lists, save time on site. We encourage feedback, record it, and compensate.

That constant cycle breeds confidence and reduces life-cycle cost, which is why so many customers stick with us for the long haul.

Partnering for Your Project

Whatever your design, a strong metal fabrication partner in Columbus, Ohio must align with your objectives, budget, and timeline while ensuring quality metal solutions stay snug and consistent from part one to 1000.

Offer personalized consultations to understand your unique metal fabrication needs and project goals.

Begin with a targeted scoping call. Specify function, volumes, environment, and target cost per unit. Send them drawings, CAD files, or even a rough sketch. A solid shop can reverse-engineer or co-develop.

Discuss end-use: HVAC housings, machine frames, food-grade guards, or outdoor enclosures. Clarify key specs: tolerance bands, for example, plus or minus 0.10 mm, flatness, hole-to-bend distances, weld symbols, and finish class.

Request case studies that take into account tight tolerances, repeatable quality, and cross-industry experience. Check certifications and shop standards applied on previous work.

Provide detailed quotes and timelines for transparent project planning.

Anticipate a line-item estimate for material grade and thickness, cutting time, forming steps, weld length, fixtures, finishing, assembly, kitting, and packaging. Terms need to call out minimum order quantities, prototype versus production pricing, and tooling or fixture costs.

Timelines should list each stage: design and engineering, material selection, cutting, forming and machining, welding and joining, finishing, and final assembly. Request practical lead times, capacity remarks, and the schedule for engineering modifications.

Demand quick, transparent quoting so decisions do not get bogged down.

Collaborate closely with clients from concept to completion for seamless execution.

Seek out a shop with laser cut, high ton press brakes, robotic welding cells and prototyping and production lines. That blend keeps your development quick and scale-up easy.

Joint design matters: pick the right joining method—MIG/TIG, spot weld, rivet, clinch, or bolted joints—based on strength, safety, and long-term service. Get design-for-manufacture input on bend radii, tab-and-slot features and weld access to cut cost and cycle time.

Ask about value-added services: in-house finishing and coating, assembly, kitting, and packaging. These steps minimize handoffs and decrease the risk of damage. Confirm quality checks at each gate: material verification on intake, first-article inspection before run, and in-process measurement to keep parts within specifications and aligned with standards.

A good partner keeps the lines of communication open with progress notes, risk flags and clear change control.

Encourage prospective customers to contact Sheet Metal Shop Columbus for a quote or consultation today.

Whether your project requires HVAC plenums, control panels, structural brackets or full enclosures, pick a shop that embraces fast prototypes, brief pilot runs and consistent production with dependable delivery.

Local support in Columbus assists with site visits, quick turn rework and tailored solutions that maintain cost while increasing performance. Contact Sheet Metal Shop Columbus to go over drawings, establish tolerances, lock materials and get a clear shot from concept to crate, with lead times that match your build schedule.

Conclusion

To close, metal work in Columbus remains powerful. That’s why shops here hit hard specs, ship on hard dates, and back it with hard skill. Local crews understand plant needs on the west side and lab build outs near OSU. That reduces risk and increases speed. A tiny little weld fix on a guard. A full frame build for a skid. A rapid laser pass for a flyer. We’ve got the tools and the people.

You want clean welds, tight bends and parts that fit on the first try. Contact us. Submit a print, a model or a sketch. Receive a transparent quote, guaranteed lead time and a build plan you can rely on. Let’s price it fair, plan it smart and ship it right. Call or even e-mail your file to begin.

Frequently Asked Questions

What industries do you serve in Columbus, Ohio?

We serve various industries including automotive, construction, medical, energy, food processing, and technology. Our full service custom metal fabrication company handles everything from prototypes to full production, meeting Ohio industrial standards and deadlines while collaborating with startups and established manufacturers.

What metal fabrication services do you offer?

We provide a wide range of services including laser cutting, CNC machining, and specialized welding services, working with materials like steel, aluminum, and exotic alloys, delivering parts ready for installation or integration.

How fast can you deliver projects in Columbus?

Lead times for custom machining and metal fabrication jobs are based on complexity and volume. Easy parts can ship in days, while bigger assemblies take a little longer. Rush orders are a priority here! We offer transparent timelines at quoting.

Do you support custom prototypes and small runs?

Yes, we provide custom machining for one-off prototypes and pilot runs. Our expertise in polishing designs for manufacture minimizes expense, maximizes quality, and accelerates manufacturing, ensuring rapid response and reliable performance.

What design files and tolerances do you accept?

We take STEP, IGES, DXF, DWG, and PDF for our custom machining processes. Normal tolerances are plus or minus 0.1 mm, with closer precision available on demand. Our team verifies key dimensions at quoting and consults on feasible specs for budget and quality.

How do you ensure quality and compliance?

ISO-aligned processes and in-process inspections ensure quality repairs for our custom machining and metal fabrication needs. We provide certificates and test reports upon request, with each job receiving dimensional checks and final QC before shipment.

Do you offer local installation or on-site support?

Yes, for qualifying projects in the Columbus region, we offer specialized welding services to assist with fit-ups, adjustments, and field welding capabilities, all while working around your schedule to reduce downtime.